PRODUCTS

Build your advantage using our high-performance soft magnetic alloys and stator and rotor stacks.

Build your advantage using our high-performance soft magnetic alloys and stator and rotor stacks.

Advancing electrification through high-performance solutions for power-dense motors.

Creating solutions that enable the electrification revolution

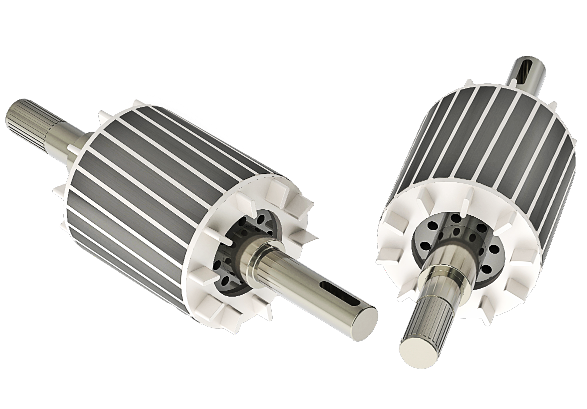

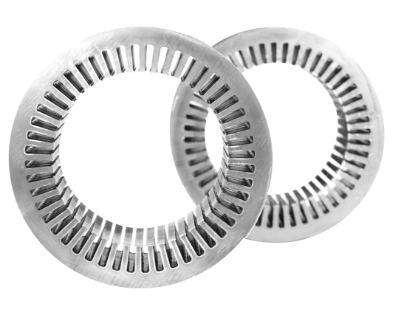

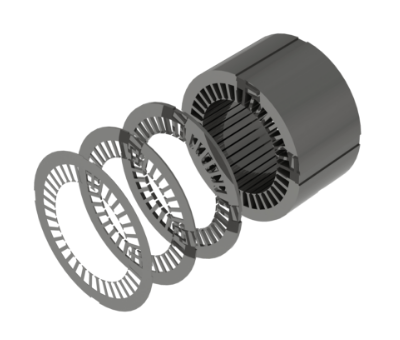

Stator & Rotor Stacks

Measurably better stack performance from best-in-class soft-magnetic materials and precision manufacturing

We’re here to support your stator and rotor stack needs, from prototype to serial production. Our range of lamination, heat treatment, bonding, and assembly techniques are optimized for quality and process yields for scalability.

Our team implements the best production method for your product given the unique performance requirements, design maturity, and volume demands based upon our expansive process datasets and experience.

Iron cobalt alloy stacks require specific knowledge about materials and stack processing technologies to create high-quality best-in-class stator and rotor stack responses. Improper processing can significantly compromise performance.

Carpenter Technology’s expertise in specialized materials and stack processing ensures the highest performance stator and rotor stacks for our customers. Our engineers have a deep understanding of metallurgical structure-magnetic property relationships and expertise in various processing technologies. Without expert processing, iron cobalt stator and rotor stacks will perform only marginally better than standard electrical steel. Our Hiperco® alloys and stack manufacturing methods for dimensional control, high-strength, and tailored magnetic properties support the most demanding motor design requirements and production tolerances, ultimately resulting in superior motor responses.

From tooling and stamping to annealing, insulation, bonding, and quality testing, Carpenter Electrification offers a simplified supply chain and short lead times for prototypes and mass production.

Hiperco alloys also work as flux concentrators in electromagnetic pole pieces for different high flux applications, such as audio voice coils and medical radiology. These alloys are also used in actuators, specialty transformers, magnetic bearing applications.

Iron cobalt alloy stacks require specific knowledge about materials and stack processing technologies to create high-quality best-in-class stator and rotor stack responses. Improper processing can significantly compromise performance.

We offer a full range of capabilities, including progressive stamping, compound stamping, notch stamping, laser cutting and EDM. With over a decade of sourcing, qualifying, and supplying laminations, we provide the market with over five million laminations per year. All products are managed per our Carpenter Technology quality control system to ensure best-in-class stack performance.

Engineered for High Performance

Our soft magnetic alloys offer up to 25% higher torque as a drop-in solution in current motor designs.

High Quality & Repeatability

With lower losses, our soft magnetic alloys can increase motor efficiency by up to 3% and power density by 30%.

Short Lead Time

Our power-dense alloys offer high-performance motors and up to 30% reduced footprint.

Our engineering team partners with designers to ensure the maximum benefits of high performance soft magnetic alloys are realized.

We're always ready to consult on your motor design and integration, and stack production. Our experts help customize solutions to your specific product and application needs, ensuring your products reach peak levels of performance.

Browse our knowledge base of technical electrification resources: white papers, brochures, datasheets, webinars, and more.