Passenger EVs

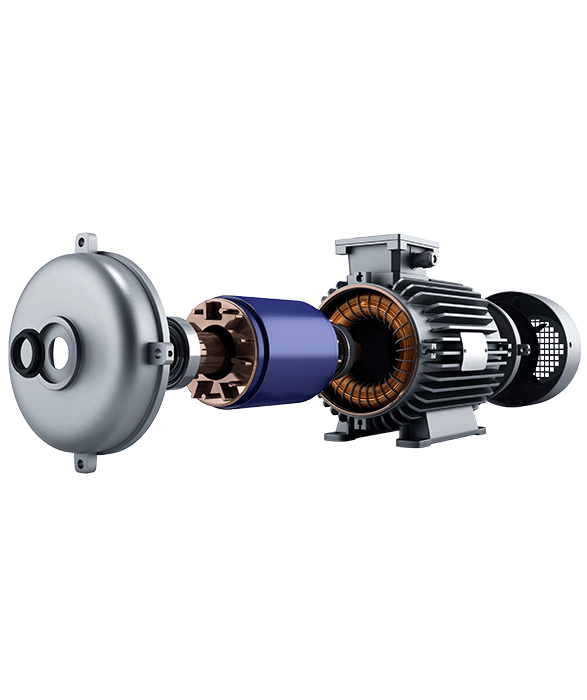

The electric supercars, luxury electric vehicles, and everyday sedan EVs of tomorrow will all sport improved motor and electronics designs for more efficient powertrains and better performance and value.

Alloys drive innovation

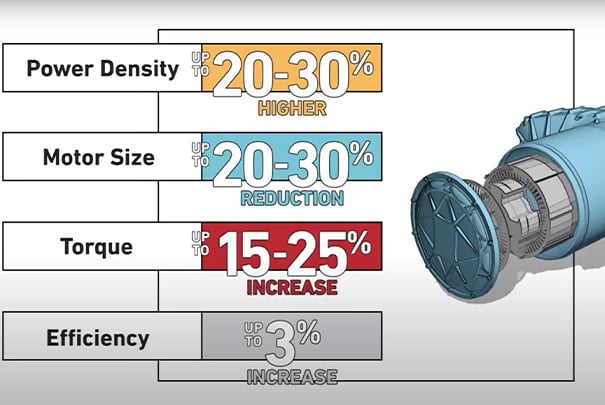

Our high-performance soft magnetic alloys enable system-level benefits for these new vehicle designs. Ideal for high-efficiency, power- and torque-dense electric traction motors, Hiperco® and Hypocore® alloys provide high induction, fast response and low core losses for better performance:

- Faster acceleration

- Extended range

- Smaller, lighter motors and batteries

Designed for advanced battery management systems, Evanohm® R resistance alloys deliver:

- Stable performance across a range of temperatures

- More accurate voltage and current regulation

Our EV alloy experts will help you meet the performance, cost, and supply needs for your high-performance electric vehicle designs.