Motors and generators for vehicle drives

Military personnel are surrounded by electrical systems requiring increasing power in confined spaces. Maneuverability and efficiency translate to agility and reach in every battle. Our soft magnetic alloys improve the range and acceleration of existing electrical drives, enabling our forces to dictate the movement of battle and fight from a position of advantage.

Electric drives for propulsion are improving the battle strength of military EVs and beyond:

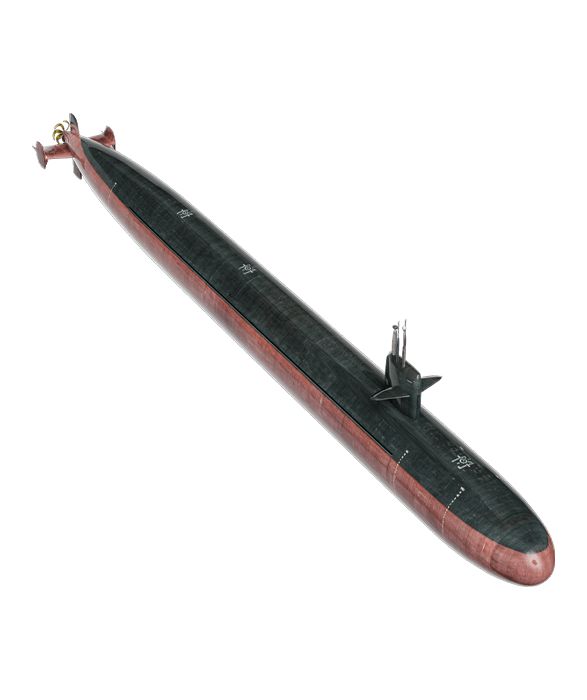

- Naval submarines and warships

- Ground assault vehicles (GAV)

- Unmanned ground vehicles (UGV)

- Unmanned aerial vehicles (UAV)

No other alloys stack up

Hiperco® and Hypocore® alloys meet the need for new system designs and provide drop-in solutions to power density challenges on legacy platforms, delivering:

- Up to 15% more torque

- Up to 3% better efficiency

- Cooler operating temperatures

- Smaller and lighter systems

- Improved reliability and longer machine life