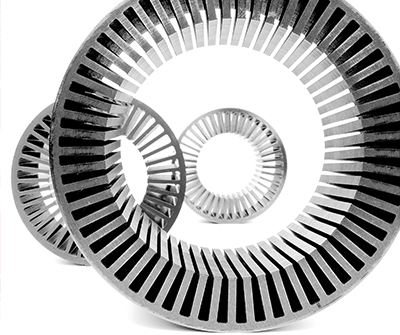

Hiperco® 50

Our Hiperco alloys provide the highest magnetic induction of any commercially available soft magnetic material while exhibiting high permeability and low core loss. These iron-cobalt alloys offer nearly 25% higher induction and 30% lower losses than conventional electrical steel.

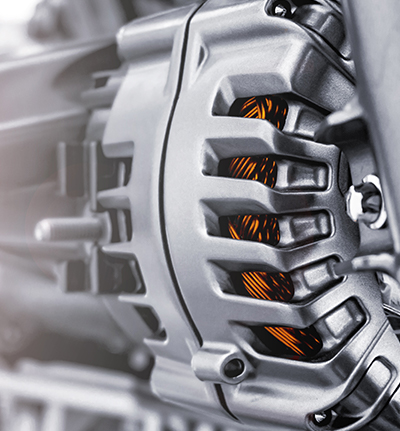

Hiperco alloys set the standard for aircraft generators and APUs, with a combination of maxi Some aircraft generators couple mum torque and power density and low losses. They help improve efficiency and typically reduce the size and weight of the generator.