TECHNICAL EXPERTISE

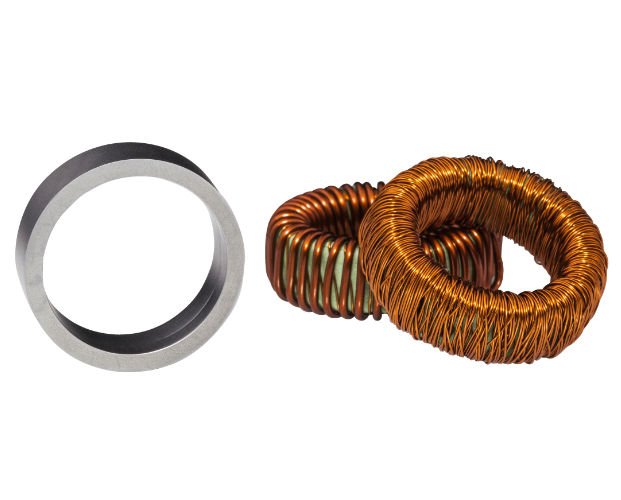

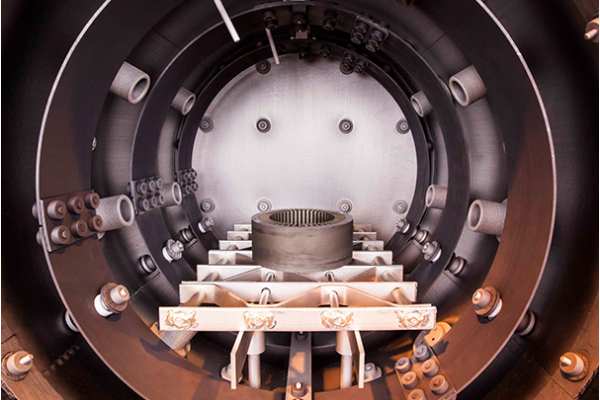

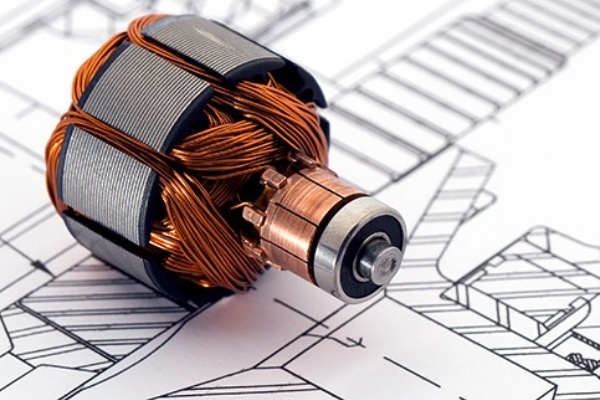

For over 80 years, we have been committed to innovation in the soft magnetic alloys business, with our materials used in generators, APUs, motors, and other high-performance applications across various end markets. As a trusted partner, we collaborate to develop and integrate high-induction magnetic materials, support material breakthroughs that increase motor performance, and exemplify our dedication to innovation.

We have built extensive technical resources, including metallurgical experts, an alloy properties database, and a processing knowledge library. These capabilities support the exploration of new, higher-performance soft magnetic alloys and facilitate repeatable production while maintaining the flexibility to address new requests and improvements quickly. Our experts actively characterize and tailor the grain growth, strength, and magnetic properties of alloys to facilitate improved downstream processing and maximize stack performance.