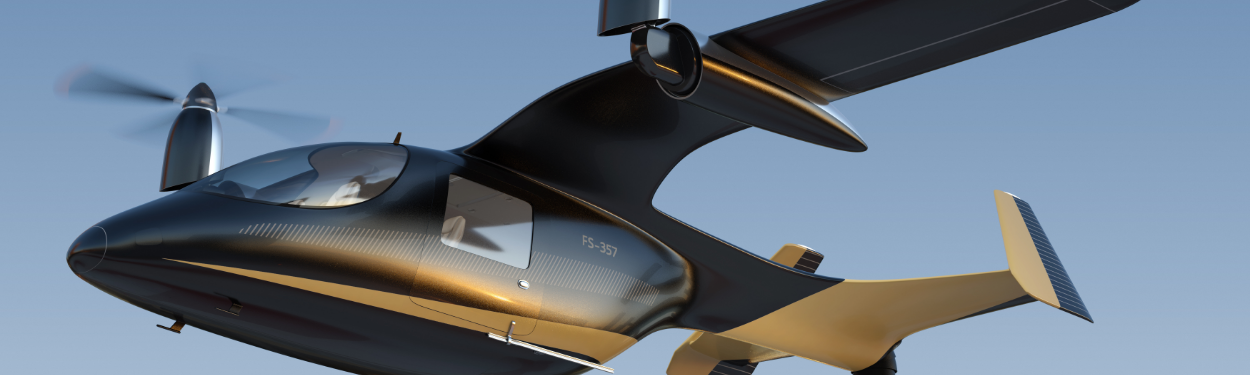

The electric vertical takeoff and landing (eVTOL) industry is poised for a revolutionary transformation in urban air mobility. As demand for eVTOLs grows, manufacturers must navigate the challenges of scaling up production to meet market needs.

In this blog, we'll explore the current state of eVTOL manufacturing, the challenges and considerations when scaling up production, and how Carpenter Electrification is poised to support this growth with our innovative stator and rotor stack solutions.

Current State of eVTOL Manufacturing

While the eVTOL industry is still in its early stages, significant plans are underway to increase production capacity. Stellantis and Archer Aviation are collaborating on a high-volume eVTOL production facility in Georgia, aiming to support the production of up to 2,300 eVTOLs annually. The eVTOL market is projected to grow from $1.2 billion in 2023 to $23.4 billion by 2030, reflecting the increasing demand and potential for eVTOLs in various applications. Additionally, companies like Joby Aviation are making progress in delivering eVTOL aircraft. Joby has already delivered its first eVTOL aircraft to the U.S. Air Force and is planning to build a scaled production facility in Dayton, Ohio. These developments indicate a growing momentum in eVTOL manufacturing and deployment.

Compared to commercial aircraft and electric vehicles, eVTOL production is still nascent. Boeing, for example, delivered roughly 450 737 airplanes in 2023 and aims to nearly double production to around 47 units per month by the end of this year. In the electric vehicle space, global sales reached around 14 million in 2023, indicating a significant increase in production to meet demand.

Scaling Up eVTOL Production: Challenges and Considerations

Scaling up production for eVTOL manufacturers involves navigating several challenges:

Safety vs. Speed

There is often a tension between rapidly scaling production to meet market demand and ensuring the safety and reliability of the aircraft. Rapid scaling can lead to compromises in safety protocols, testing, and quality control, which can be detrimental in the long term. Manufacturers must find a balance between accelerating production and maintaining rigorous safety standards.

Factory Size and Layout

As production scales, the size and layout of manufacturing facilities become critical. Factories must be large enough to accommodate increased production volumes and efficiently designed to optimize manufacturing. Space constraints or inefficient layouts can lead to bottlenecks and delays.

Quality Management

Maintaining high-quality standards becomes more complex as production scales. Implementing robust quality management systems and continuous monitoring ensures that each component and final product meets the required specifications and safety standards.

Supply Chain Coordination

Different components of eVTOLs, such as wings, electric motors, and avionics, are often manufactured in various locations, sometimes by different suppliers. Coordinating the production and assembly of these components to ensure they meet the required specifications and are delivered on time for assembly can be challenging. Misalignment in production rates or quality discrepancies between components can lead to delays and increased costs.

Integration of Advanced Technologies

eVTOLs rely on advanced technologies, including electric propulsion systems, sophisticated flight control software, and autonomous navigation systems. Integrating these technologies into manufacturing while scaling up production requires sophisticated engineering capabilities and can introduce complexity.

Workforce Training and Retention

Scaling up production requires a larger workforce with specific skills. Training new employees and integrating them into the production process while also retaining experienced workers can be challenging, especially in a competitive labor market.

Financial Risks

Expanding production capacity often requires significant capital investment. A substantial financial risk is involved if the market demand does not grow as expected or if there are delays and cost overruns in scaling up the production.

Regulatory Compliance

Compliance with aviation regulations becomes more complex as production scales. Manufacturers must ensure that all components and processes comply with regulatory standards, and any changes or scale-up in production may require additional certifications or approvals.

Carpenter Electrification: Powering the Future of eVTOL Motors

At Carpenter Electrification, we understand the critical role of electric motors in eVTOL performance. Our materials science and advanced manufacturing expertise allows us to develop stator and rotor stacks that deliver optimal performance.

Our proprietary Hiperco®50 alloy is a game-changer in electric motor materials. With nearly 25% higher induction and 30% lower losses than conventional electrical steel, Hiperco®50 enables maximum torque density and minimizes losses in motors and generators. Electric motors built with our high-performance stators and rotors can improve power density by 20% to 30%, enabling significant weight savings for various applications.

With continuing strategic investments in electrification, Carpenter Electrification is well-positioned to keep pace with advances in eVTOL manufacturing. Our "Production at Scale" model ensures we can meet the growing demand for stator and rotor stacks as the eVTOL industry scales up.

Scale Up with Carpenter Electrification

As the eVTOL industry prepares for takeoff, manufacturers must navigate the challenges of scaling up production while maintaining safety, quality, and efficiency. By addressing the challenges and considerations outlined in this blog post, eVTOL manufacturers can effectively scale up production to meet the growing demand for urban air mobility solutions.

At Carpenter Electrification, we are committed to supporting this growth with our innovative stator and rotor stack solutions. If you're ready to scale up, our team will help address your motor design needs for current and future eVTOLs.