Hybrid and full-electric aircraft

The commercialization of electric aircraft will transform air travel, bringing more flexible, convenient, and clean transportation to people around the world:

- Electric vertical takeoff and landing (eVTOL) aircraft

- Hybrid and full-electric airplanes, and e-copters

- Flying cars and hover bikes

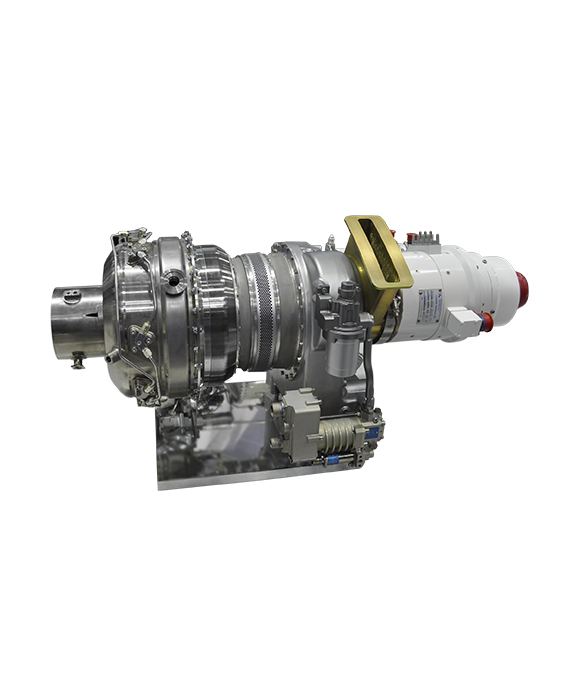

Optimizing power density

In order for large-scale aircraft electrification to become a reality, electric aircraft will need high-output generators and motors with compact form factors. Our high-induction Hiperco® alloys give e-motor designers the materials they need to achieve:

- High power density

- High torque density

- Reduced size and weight

Stacking up performance

Our advanced stator and rotor stack manufacturing capabilities enable the use of thin Hiperco® laminations, ideal for high-speed motors and generators:

- Low core loss

- Continuous power operation

- Lower operating temperatures