The Science Behind Thin Laminations for High-Frequency Motor Applications

| 6 min read

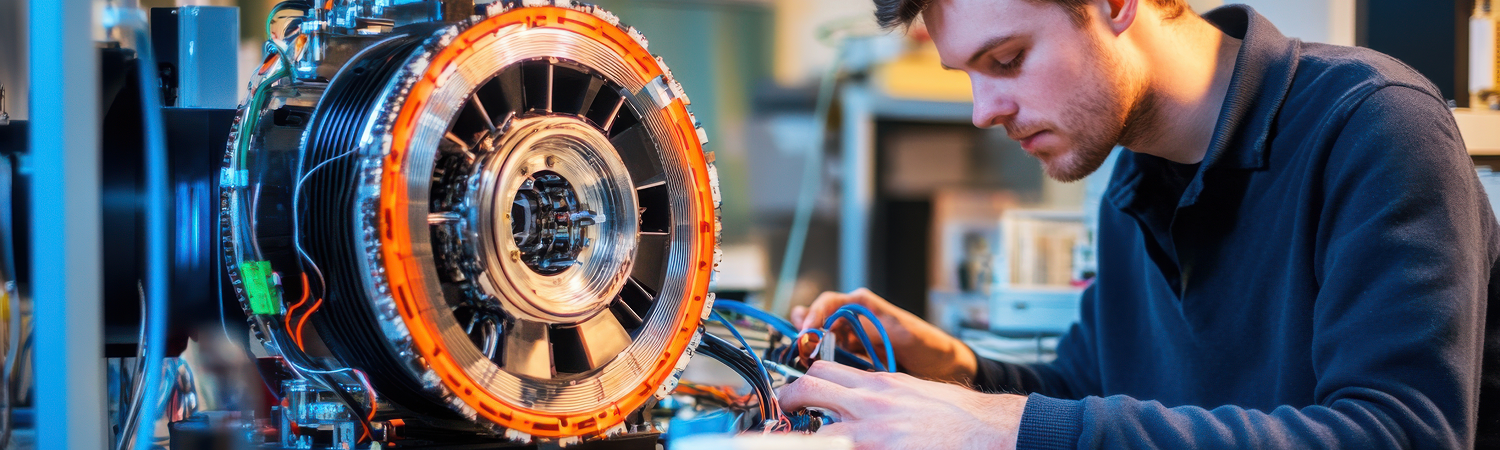

The push for higher power density and improved efficiency in electric motors spans virtually every industry. Engineers face mounting pressure to deliver motors that are smaller, lighter, and more efficient, enabled by advances in silicon carbide (SiC) and gallium nitride (GaN) power electronics that allow motor drives to operate at previously impractical frequencies.

However, these higher switching frequencies introduce new challenges.

Traditional lamination thicknesses become a significant limitation when operating above 800 Hz, as the relationship between operating frequency, lamination thickness, and core losses becomes increasingly critical. Let’s explore in more detail.

Why Traditional Designs Fall Short

As switching frequencies rise beyond traditional ranges, core loss mechanisms undergo a dramatic shift. What works efficiently at 400 Hz can become a significant source of losses at 1500 Hz or higher, primarily due to increased eddy current losses when using traditional lamination thicknesses.

This challenge is particularly acute across today's electrification landscape. Electric vehicles must match the high switching frequencies of their SiC inverters. Hybrid and electric aircraft demand the extreme power density that only high-frequency operations can deliver. Defense systems, drones, and precision medical equipment all push beyond what's possible with traditional motor designs.

Understanding Frequency-Induced Losses in Motor Cores

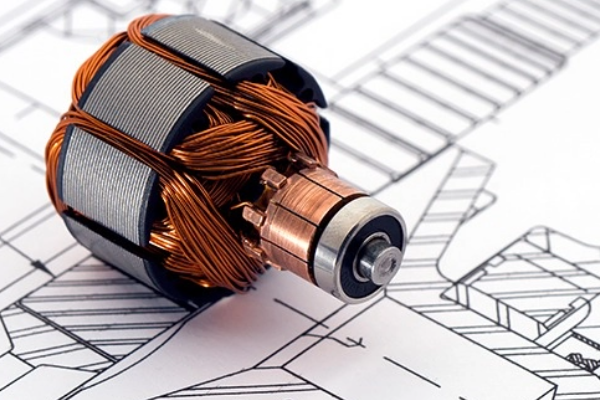

Motor core losses consist of two primary components that behave very differently as frequency increases. Understanding these loss mechanisms is essential for selecting the appropriate lamination thickness.

Eddy Current Physics at High Frequencies

Eddy current losses in laminations increase proportionally to the square of both the operating frequency and the lamination thickness. This quadratic relationship indicates that as frequencies increase, the impact of lamination thickness on overall losses becomes increasingly pronounced.

At standard operating frequencies below 400 Hz, eddy current losses may represent a manageable portion of total core losses. However, as frequencies climb into the kilohertz range, these losses can quickly dominate.

The physics relates to induced currents that circulate within the conductive lamination material when exposed to alternating magnetic fields. Thinner laminations restrict the paths available for these currents, effectively reducing their magnitude and the associated losses.

The Crossover Point

A critical concept in high-frequency motor design is the crossover point—the frequency at which eddy current losses begin to exceed hysteresis losses. Operating above this crossover frequency without adjusting lamination thickness results in rapidly escalating losses that can compromise motor performance.

Our analysis of Hiperco® 50 demonstrates this principle. The crossover point shifts to higher frequencies as lamination thickness decreases, providing a wider operational range before eddy currents dominate. This relationship underscores why traditional lamination thicknesses become inadequate for high-frequency applications.

Modern Applications Driving Ultra-Thin Lamination Demand

The push toward higher operating frequencies stems from specific advantages that directly address modern engineering challenges.

SiC/GaN Inverter Requirements

Silicon carbide and gallium nitride power electronics have revolutionized motor drive capabilities, enabling switching frequencies from 20 kHz to over 100 kHz. These advanced semiconductors offer significant advantages:

- Lower switching losses that maintain efficiency at high frequencies

- Higher temperature operation capability, reducing cooling requirements

- Faster switching transitions that enable more precise motor control

- Smaller passive components due to higher switching frequencies

However, realizing their full potential requires motor designs that can handle elevated frequencies without excessive core losses. Standard lamination thicknesses become significant bottlenecks when paired with SiC or GaN devices.

Additional High-Frequency Applications Across Industries

Modern applications across industries are pushing frequency boundaries based on unique performance requirements, including:

- Electric aircraft propulsion - Distributed propulsion systems operate at 2000-4000 Hz to achieve critical power density for flight, where every gram of weight reduction matters.

- High-speed industrial machinery - Compressors and turbo equipment run at 1500-3000 Hz to minimize footprint while maintaining efficiency in challenging environments.

- Medical and surgical devices - Precision tools and imaging equipment push into ultrasonic frequencies, demanding compact size with absolute reliability.

- Defense systems - Military applications require operation at extreme frequencies while maintaining performance in harsh conditions.

These diverse applications share a common need: achieving maximum performance from minimal size and weight, making optimized thin laminations essential for meeting their demanding specifications.

Calculating Optimal Thickness

Selecting the appropriate lamination thickness requires balancing multiple factors, with operating frequency being the primary driver.

Frequency Bands and Recommendations

Based on extensive analysis of hysteresis and eddy current loss contributions in our Hiperco® alloys, we've established optimal thickness ranges:

- For 300-800 Hz applications, 0.15 mm Hiperco® laminations deliver an optimal balance of performance and manufacturability. As frequencies increase to 800-1800 Hz, transitioning to 0.10 mm laminations becomes necessary. The reduction in thickness results in a significant decrease in eddy current losses, which more than compensates for any increase in processing complexity.

- For applications exceeding 1800 Hz, even thinner laminations are recommended. Some extreme applications may benefit from laminations as thin as 0.05 mm, though these require specialized handling and processing techniques.

Using Loss Data for Selection

The core loss data table provides quantitative guidance for material selection. At 0.10 mm thickness, Hiperco® 50 shows core losses of 19 W/kg at 400 Hz, increasing to 52 W/kg at 1000 Hz. Comparing this to 0.25 mm thickness at the same frequencies (24 W/kg and 102 W/kg, respectively) demonstrates the substantial benefit of thickness reduction at higher frequencies.

Material Processing Advances for High-Frequency Performance

Achieving optimal performance from thin laminations requires more than just reducing thickness. The magnetic and mechanical properties of our alloys can be fine-tuned through processing techniques that directly impact high-frequency performance.

Our controlled processing approach optimizes materials for specific frequency ranges:

- Thermal treatment optimization - Precise heat treatment modifies grain structure, allowing us to shift the optimal frequency range for a given thickness.

- Stress relief protocols - Controlled stress relief improves permeability and can reduce core losses by up to 20% in high-frequency applications.

- Surface finish refinement - Specialized finishing processes minimize losses while maintaining proper insulation integrity.

- Advanced coating systems - Our coatings achieve a consistent thickness of 1-2 microns while maintaining breakdown voltages for high-frequency operation.

This processing flexibility proves valuable when balancing performance against cost. Through optimization, we can extend the frequency range of standard thickness laminations, avoiding the premium of ultra-thin materials when peak performance isn't essential.

Manufacturing Challenges: Producing Ultra-Thin Laminations at Scale

The production of ultra-thin laminations presents unique manufacturing challenges. Stamping tolerances become critical as thickness decreases, and the inherent growth of iron-cobalt alloys like our Hiperco® materials must be carefully predicted and compensated for in die design.

Edge quality control is paramount in high-frequency applications — burrs or deformation can create shorting paths that dramatically increase losses. Advanced cutting techniques must be optimized for each thickness range to maintain quality while achieving production efficiency.

Stack assembly complexity increases with thinner laminations as more layers require precise handling and alignment. Automated stacking systems become essential for maintaining quality at production volumes while minimizing the risk of damage during assembly.

Cost vs. Performance: When Thinner Isn't Always Better

While thinner laminations generally provide better high-frequency performance, the relationship between thickness reduction and system-level benefits isn't always linear. The cost implications extend beyond raw material expenses to include increased processing complexity, reduced manufacturing yields, and longer assembly times.

A motor operating at 600 Hz, for example, may show only marginal loss improvement when moving from 0.15 mm to 0.10 mm laminations, but the thinner material could increase stack costs by 30-40%. Understanding these trade-offs enables designers to optimize for total system value rather than pursuing maximum technical performance at any cost.

Partnering for High-Frequency Motor Excellence

The transition to high-frequency motor operation represents both a challenge and an opportunity. Success requires a deep understanding of the relationships between operating frequency, lamination thickness, and core losses, combined with expertise in material processing and manufacturing techniques.

We combine materials expertise, processing knowledge, and manufacturing capabilities to support the development of high-frequency motors. Our Hiperco® alloys, developed and refined over decades, provide the foundation for superior high-frequency performance. Our application engineers understand the complex trade-offs involved in lamination selection and can help identify the optimal combination of alloy grade, thickness, and processing approach for your specific application.

Ready to optimize your high-frequency motor design? Contact our team today.