Past to Future: The Electric Powertrain Revolution Reshaping Performance Cars

| 6 min read

The electric vehicle landscape has undergone a dramatic transformation since 2017, when high-performance electric vehicles (EVs) first surpassed the 700-horsepower threshold. What seemed revolutionary then — Tesla producing 40,000 cars with 700+ hp — now represents the baseline for premium electric performance. Today's EVs can routinely exceed 1,000 horsepower, with manufacturers pushing boundaries that would have seemed impossible just a few years ago.

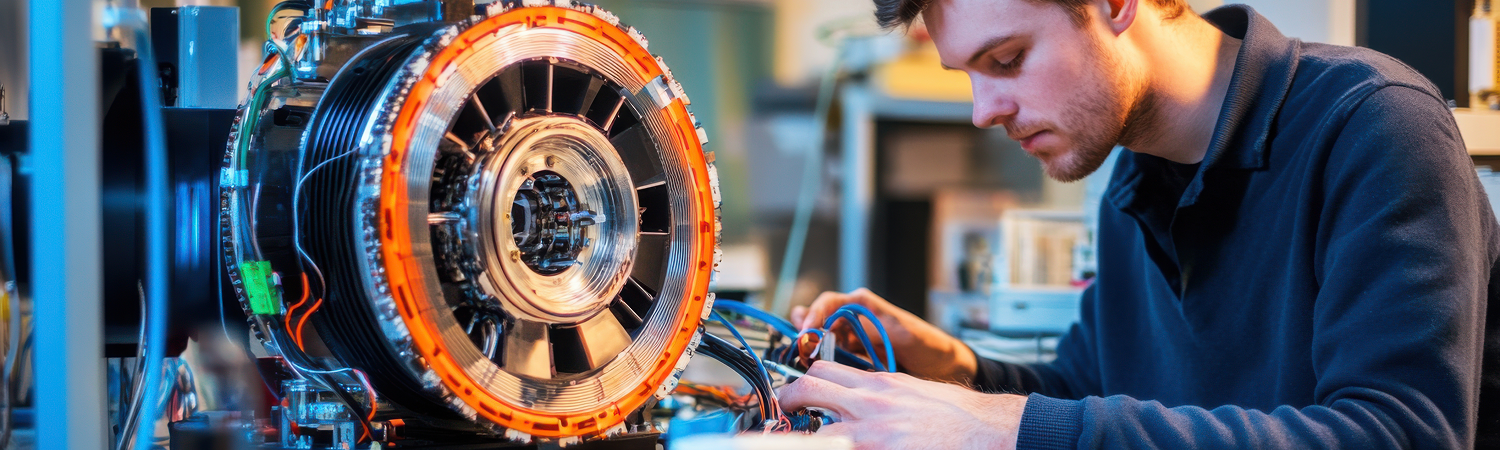

This evolution reflects more than incremental improvements. The convergence of 800V architectures, silicon carbide inverters, and advanced motor designs has fundamentally redefined what's possible in electric powertrains. But at the heart of this transformation lies a crucial component: the soft magnetic materials in the motor — the core of the EV powertrain — that enable unprecedented power density and efficiency.

The Evolution of Electric Vehicle Performance

The journey from niche environmental statement (with over one million EVs sold globally in 2017, most under 500 hp) to performance benchmark (with over 17 million globally, ranging from 200 to 1000+ hp) occurred faster than most industry observers predicted.

In 2020, vehicles with more than 500 hp accounted for just 4.1% of total EV sales. Current data indicate that this segment has experienced significant expansion with absolute volumes increasing even more dramatically as overall EV adoption accelerates.

The high-performance EV market, comprising EVs with 500 hp or more, is projected to reach approximately 25 million units by 2030. The global luxury electric vehicle market, including those with powerful drivetrains, was estimated to be worth $223.05 billion as of the end of 2024.

From Pioneers to Today's 1000+ HP Capabilities

The performance (and luxury) ceiling has risen consistently. Lucid's Air Sapphire delivers 1,234 hp, while Rimac's Nevera delivers with 1,888 hp, and Porsche's Taycan Turbo GT achieves 1,019 hp using advanced motor design materials.

But reaching these power levels creates competing demands. Engineers need motors that are simultaneously more powerful, more efficient, and smaller—all while managing extreme thermal loads. This is where material science becomes critical.

The Advanced Magnetic Materials Advantage

Three critical factors determine electric motor performance: power density, torque, and efficiency. Traditional electrical steel reaches its practical limits below 2.0 Tesla saturation, constraining what is achievable.

Advanced soft magnetic alloys, such as Carpenter Electrification's Hiperco® 50, achieve saturation levels of up to 2.4 Tesla, providing the high induction, fast response, and low core losses necessary for superior stator and rotor stacks (what’s used to power the electric motor) performance in these EV powertrains.

This delivers measurable improvements across all three critical factors:

Power Density and Motor Size

The higher magnetic saturation of advanced alloys enables engineers to achieve more power from less material. This fundamental advantage transforms motor design possibilities:

- Up to 20-30% higher power density

- Up to 20-30% reduction in motor size

- Enables lighter, more compact powertrain designs

Torque and Acceleration

Advanced magnetic materials allow motors to generate stronger magnetic fields without proportionally increasing current draw. This translates directly to improved vehicle performance:

- Up to 15-25% torque increase

- Faster acceleration response, sometimes up to 20% faster (most mainstream EVs have 0-60 mph times in the 4-7 second range)

- Maintained performance at high switching frequencies (20+ kHz with SiC inverters)

Efficiency and Range

Lower core losses and improved magnetic response reduce energy waste throughout the motor's operating range. These efficiency gains compound to deliver real-world benefits:

- Up to 3% efficiency increase

- Significant reduction in energy consumption during city driving

- Industry-leading efficiency for extended range

System-Level Benefits

These motor improvements cascade throughout the entire powertrain:

- Battery size reduction while maintaining range

- Lower thermal stress with operating temperatures reduced by up to 60°C

- Increased powertrain reliability through reduced heat generation

- Significant cost savings from downsized components

- Weight reduction from smaller motors and batteries

The Road Ahead: 2025 and Beyond

Higher performance targets from manufacturers mean intensifying demands on motor technology. Electric aviation represents another frontier, with eVTOL aircraft targeting 20 kW/kg at the motor level. Commercial vehicle electrification presents different challenges, requiring sustained high torque while managing thermal constraints.

The sustainability narrative increasingly influences purchase decisions in premium segments. Improved motor efficiency reduces lifetime energy consumption, while smaller motors require less raw material. Advanced magnetic materials enable the more efficient use of critical materials, such as rare earth magnets and copper, demonstrating superior lifecycle performance through improved efficiency, reduced size, and extended operating life.

As 2025 progresses, the convergence of performance demands, efficiency requirements, and environmental considerations will continue driving innovation in motor materials. The manufacturers who leverage these advanced material capabilities will define the next generation of electric vehicle performance.

Ready to Push the Boundaries of Electric Motor Performance?

The industry's push toward more ambitious targets makes advanced soft magnetic alloys increasingly critical. Our team can help you leverage advanced soft magnetic alloys to create motors that deliver exceptional power density, torque, and efficiency. Contact our experts today to discuss how Hiperco® 50 and our complete portfolio of soft magnetic materials can transform the motor at the heart of your next EV powertrain.