Electric propulsion in aerospace may pave the way for a new era of low-emission, low-noise, and even potentially safer flights. The last few years have seen an increasing number of development programs focused on aerospace electrification across the globe, most focused on urban air taxis and short-haul flights. Aerospace innovators are looking even further afield, examining several electrification options based on flight size, travel distance, and load-carrying capability. In contrast with conventional aircraft that typically use no electric power for propulsion:

- All-electric aircraft rely on battery-generated electric power.

- Hybrid electric aircraft use a combination of fuel and electrical energy storage.

- Turboelectric aircraft use combustible fuel for energy storage and electrical power transmission to drive the propulsor (as opposed to mechanical power).

To make the electric dream a reality, the industry must close the technology gap to electric propulsion — primarily defined by the output power required for flight.

Power output varies by platform type, including general aviation aircraft, urban air taxis, regional aircraft, and large commercial aircraft. Technology challenges include batteries, electric motors, generators, high voltage wiring, and power electronics, among others.

Battery power density

The biggest technology challenge is battery power density, which is 4-10 times lower than what would be needed for an all-electric regional commuter aircraft with reasonable range, size, and load-carrying capability. For long-haul commercial flights, the gap between current and required battery power density is even greater. Present-day battery technology does allow for short-range, sub-regional civil aviation using electric vertical takeoff and landing (eVOTL) or conventional technologies — for example, a 100- or 200-mile commute with a few people on board. These short-range electric flight options are a commercially attractive alternative to fuel-powered aircraft and helicopter flights in terms of cost, safety, and noise.

High-torque and power-dense motors

Electric motor technology is the crux of aircraft propulsion — crucial for efficient electric flying. Power- and torque-dense motors can improve the thrust needed during takeoff and landing and save power during flying operations, enabling longer flight ranges or more load or passenger-carrying capability. For short-haul flights, efficient motor technology is particularly important since takeoff and landing can consume a significant portion of the total energy required for the flight.

Different design options, such as selecting premium stator and rotor materials as well as optimizing winding and cooling technology, can play a pivotal role in realizing power- and torque-dense motor solutions.

High-performance soft magnetic alloys from Carpenter Technology with high induction and low loss in the stator and rotor stacks can offer a significant boost in motor torque and power density.

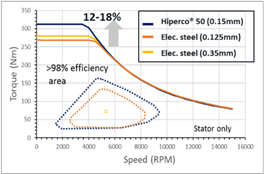

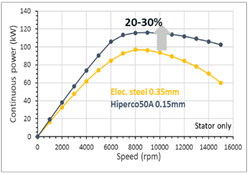

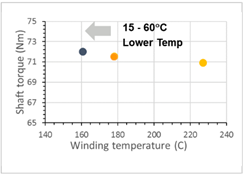

Design-optimized motors using Carpenter Technology alloys and stack solutions can provide nearly 12-18% higher torque density, 20-30% higher continuous power density, and a significant reduction in motor temperature during operation versus conventional Si-steel stacks. Torque-dense motors using Carpenter solutions can have 1-3% higher efficiency, may require significantly less complicated cooling, and may help realize faster flight acceleration, improved range, and passenger-carrying capabilities for short-haul eVOLTs and conventional flights.

PM motor responses with Carpenter Technology high induction alloys

Improved torque, efficiency, and design freedom

Higher continuous power density

Better thermal management

Click here to see how Carpenter Electrification is powering next-generation aerospace motors or contact us today to ask your own questions!